The processing on the perfume glass bottle is to be more attractive, so many customers will perform a lot of processing procedures on the glass bottle in order to be better accepted by the users.

There is another process for perfume bottles, which is decals, which are also divided into high temperature and low temperature.

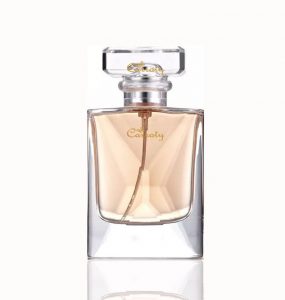

perfume bottle

Generally, we also choose high-temperature decals. The effect of high-temperature decals is the same as that of high-temperature printing, but the color can be more than that of printing, which is like printing with more than 3 colors. We generally use decals. The decals are used for comparison. Multi-color printing on it. Of course, there are also, for example, more complicated bottles. The shape of the bottle is special and there is no way to print. It can also be decals, which are more flexible. Low-temperature decals are more troublesome, because after decals (printing), there will be a protective film on the surface. This protective film protects the decal paper from damage during the pasting process, and the shape and font of the flower are generally attached. It is on this layer of film, so after it is pasted, we will have to leave it for about two days before we can tear off this layer of film without damaging the pattern and font shape, and then we can bake it. Low-temperature flower lines and fonts are the same as low-temperature printing, which is more three-dimensional, but you can’t touch the alcohol.

Whether it’s printing, decals, or labeling after low temperature processing, these things can be processed at high temperature. If defects in low temperature processing are found, they can be baked at a high temperature exceeding 580 degrees. After baking, the low temperature Processing will evaporate.